Why Seamless?

Harnessing the myriad technical advantages of complex metal spinning to create drum sound in its truest form.

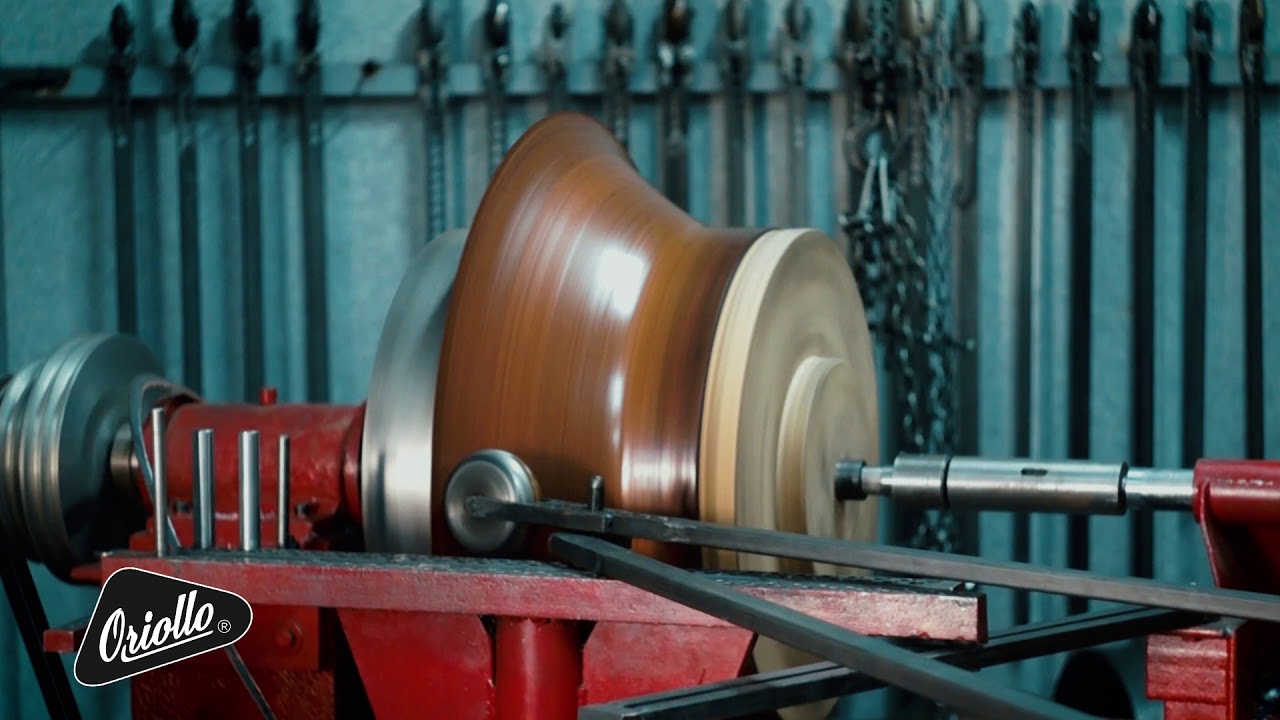

The metal spinning process improves the raw material metallurgically by realigning the grain structures - repeated passes with the tool work harden the material.

Combine such structural integrity and strength of the shell with its thinness and you have a shell that is superior to any seamed shell - you have a highly resonating shell, full of tone!

Also, the grades of metals we're using for metal spinning are not easily obtainable and differ from the grades used in rolled/welded shells. That's the case with our medium manganese steel, but our aluminum, brass and copper are obtained in special grades as well.

Brass and copper are also annealed before and during the process of metal spinning.